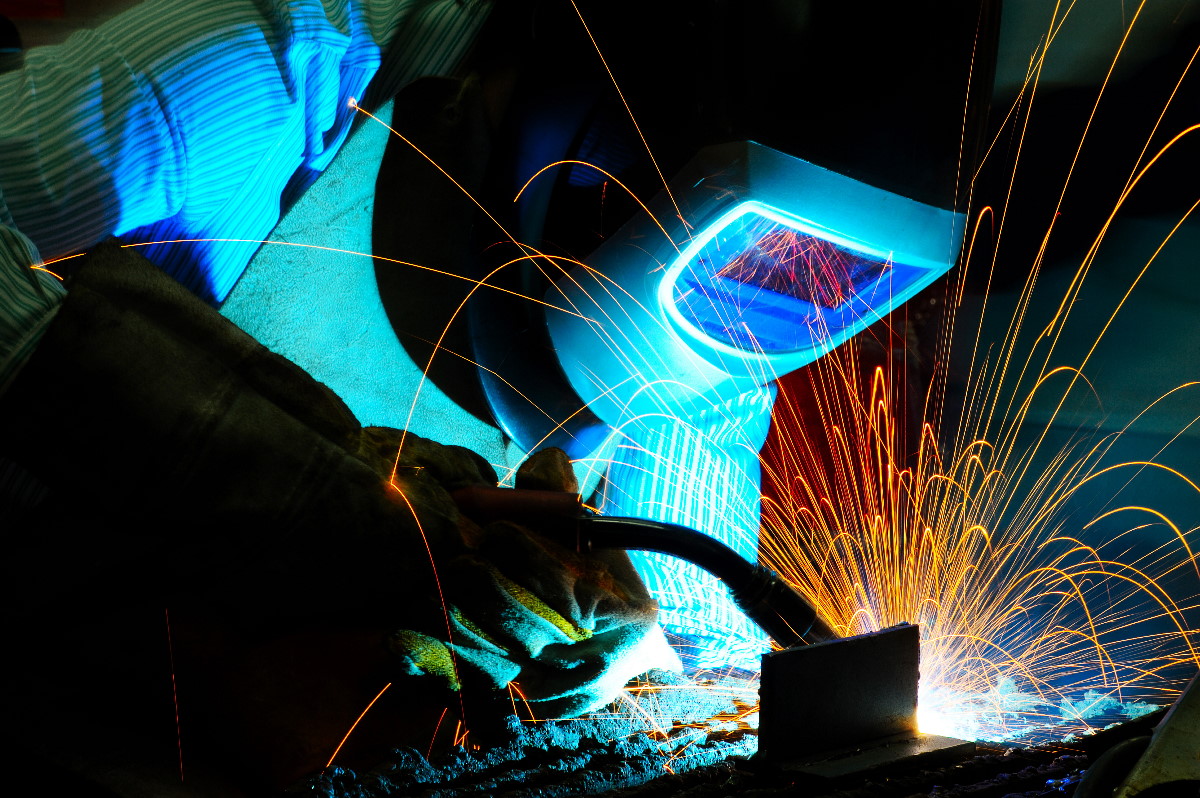

Welding services

When it comes to welding services for steel and aluminum, our company stands out as a reliable and skilled provider. With expertise in TIG and MIG welding techniques, we offer superior welding solutions that meet the highest industry standards. Advantages of our welding services, focusing on steel and aluminum welding. Additionally, we will highlight our ability to machine parts after welding, ensuring precision and accuracy.

Steel Welding:

Steel welding plays a crucial role in various industries due to the versatility and strength of steel as a construction material. Our welding services excel in steel welding, utilizing advanced techniques to join steel components with precision and structural integrity. Whether it's mild steel, stainless steel, or high-strength alloys, our skilled welders have the expertise to deliver high-quality welded assemblies for diverse applications.

Aluminum Welding:

Aluminum welding is essential in industries that require lightweight and corrosion-resistant structures. Our welding services extend to aluminum welding, where we specialize in joining aluminum components with exceptional skill and precision. With our expertise in handling various aluminum alloys, we ensure strong and durable welds that meet the specific requirements of your project.

TIG Welding:

Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW), is a highly precise welding process that produces clean and high-quality welds. Our welding services include TIG welding, where we utilize a non-consumable tungsten electrode to create precise and controlled welds. TIG welding is suitable for both steel and aluminum, offering excellent control over heat input and minimizing distortion.

MIG Welding:

Metal Inert Gas (MIG) welding, also known as Gas Metal Arc Welding (GMAW), is a versatile welding process commonly used for its efficiency and ease of operation. Our welding services encompass MIG welding, providing robust and efficient welds for steel and aluminum components. With the use of a consumable wire electrode, MIG welding enables high-speed welding while maintaining quality and strength.

Parts Machining after Welding:

In addition to our welding expertise, we offer machining services for parts that require further processing after welding. Our skilled machinists utilize state-of-the-art equipment and precision tools to machine welded assemblies to precise specifications. This capability ensures that the welded components meet the required tolerances and dimensions, enhancing the overall quality and functionality of the finished product.

Advantages of Our Welding Services:

Skilled Welders: Our team of experienced welders possesses the necessary expertise to handle complex welding projects with precision.

Quality Assurance: We adhere to stringent quality control measures to ensure that every weld meets the highest standards of strength, durability, and aesthetics.

Versatility: Our welding services cater to a wide range of industries, accommodating different materials, thicknesses, and project requirements.

Efficient Turnaround: We prioritize timely delivery without compromising on the quality of our welding services.

Customization: We work closely with our clients to understand their specific welding needs, providing tailored solutions to meet their unique requirements.

As a reputable provider of welding services, we specialize in steel and aluminum welding using TIG and MIG welding techniques. Our skilled welders and state-of-the-art equipment ensure superior weld quality, structural integrity, and precision. Additionally, our machining capabilities allow us to deliver welded assemblies with precise dimensions and tolerances. Whether you need welding services for steel or aluminum components, our expertise and commitment to excellence make us the ideal partner for your welding needs. Contact us today to discuss your project requirements and experience the exceptional quality of our welding services.